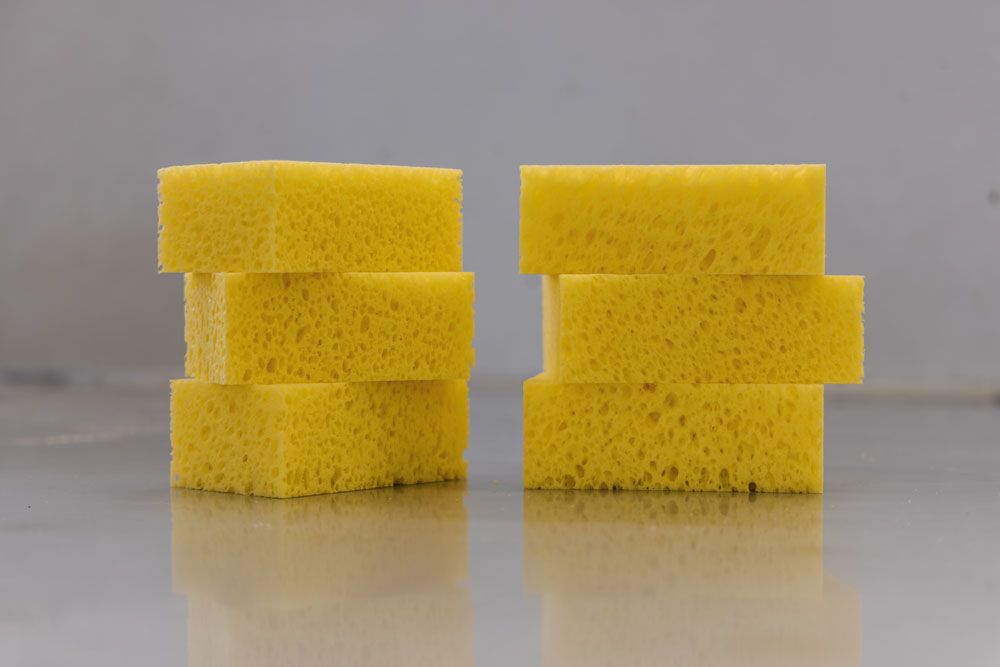

Open-cell soft foams (HS, HN , HF)

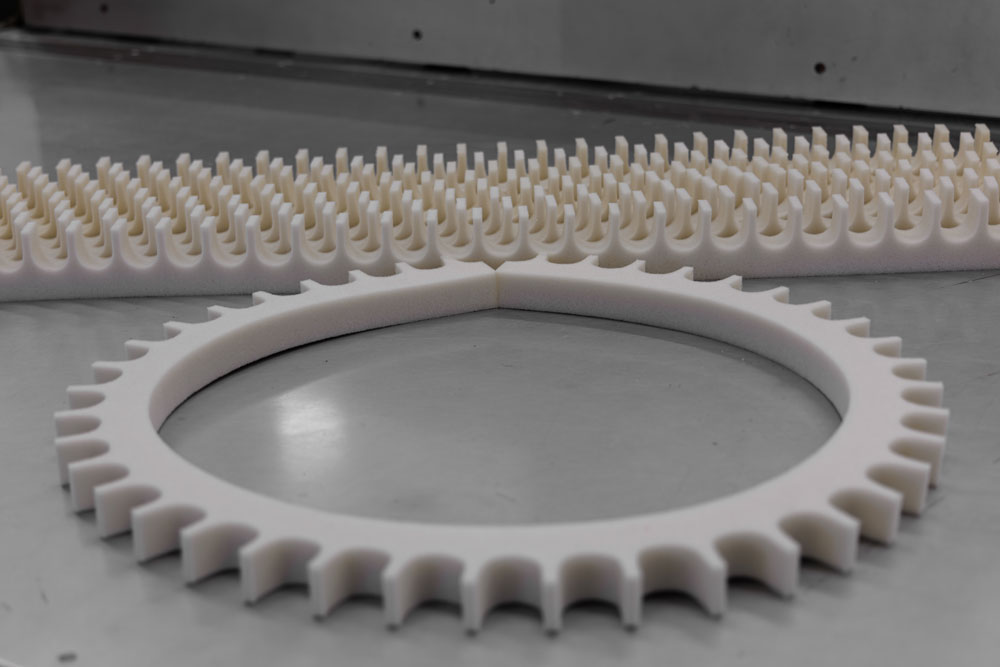

- Net Sponges

- Finishing of Porcelain and Ceramics

- Soft Foam Filters for Plasma Systems

Soft foams HS

Soft foams HN

Soft foams HF

- Abrasiveness (particle residues)

- Water absorption

- Density

- Dimensional stability

- Compressive strength

- Air permeability

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Fine-pored soft foams (ESRH, RSRT)

- Finishing of Ceramic Surfaces

- Machine Processing of Raw Ceramics

- Precision in Applying Care Products

Soft foams ESRH

Soft foams RSRT

- Abrasiveness (particle residues)

- Water absorption

- Density

- Dimensional stability

- Compressive strength

- Air permeability

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

What do PUR foams achieve and how are they used in industry?

Polyurethane foams are extremely versatile materials with a wide range of application possibilities.

Thanks to their open cell structure and elastic cell walls, they are highly flexible while offering high dimensional stability depending on type. The open cell structure also ensures good air permeability and liquid absorption. These properties make PUR foams ideal for use in the following sectors & industries:

- Porcelain & Ceramics Industry

- Glass Industry

- Optical Industry

- Gastronomy

- Wood & Metal Processing

- Leather Processing Industry

Polyurethanes belong to reactive plastics typically consisting of two raw material components along with additives such as color pigments fillers blowing agents when it comes to foams. The raw material components are polyols isocyanates which react with blowing agent form PUR. The blowing agent forms gas inclusions leading cells pores within foam. Depending on application purpose there different hardness grades ranging from soft semi-hard hard.

PUR foams characterized their open-cell structure where cell walls burst during final phase foaming process.

There polyester polyether foams differing technical properties. Additionally, PUR foams mainly vary density compression hardness cell structure. Density indicates foam's weight per unit volume while compression hardness indicates firmness foam. Cell structure influences mechanical properties foam controlled accordingly.

Macro shots on this page give insight into unique features different types available beyond those shown numerous others available. Ester Foams have densities ranging from 18 - 60 kg/cbm very regular cell structure good shock absorption. Ether Foams have densities ranging from 16 - 80 kg/cbm open cell structure high elasticity. Sponge Foams have natural sponge-like cell structure high tear resistance special sponges wide color variety consumer advertising purposes.

Products by Sponge Type

CUTTINGS

OVAL SPONGES

SPONGE ROLLS

SPONGE ROLLS

GEOMETRIC

SPONGE BANDS

SPONGE WEDGES

Innovative Production Specialty Sponges

Our manufacturing technologies have set standards since switching machine processing PUR sponges. We ensure best quality raw materials during procurement maintain this standard throughout entire production process. Learn how our high-performance sponges efficiently manufactured meet demanding requirements customers.

Watch our video!