Industrialization

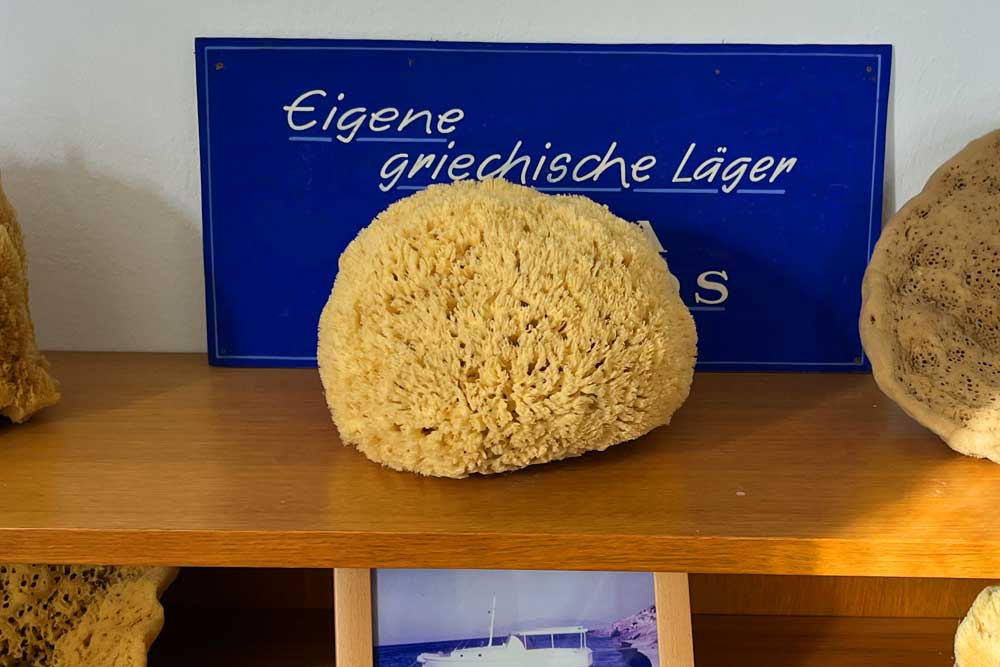

Over the years, circumstances changed: In the 1970s and 1980s, the availability of natural sponges decreased, presenting new challenges for the company. In response, ZERVOS underwent a significant transformation and began manufacturing polyurethane foams (PUR sponges). This step was driven by the goal to continue providing suitable sponges and products to the industry.

Tradition as a Success Guarantee

Since the 1980s, ZERVOS has established itself as a leading producer in the field of PUR specialty foams for the ceramics industry. The company's sponges are the result of many years of experience and continuous quality improvements. These developments have allowed ZERVOS to solidify its market position and today it is synonymous with high-quality industrial sponge products that originated from traditional craftsmanship.

The Zervos-Manufacturing Concept

In the ceramics industry, assembly line production has been used since the 1990s. The equipment of these machines with sponges often occurs in large quantities. ZERVOS has never lost sight of the fact that besides meeting the needs of large industrial companies, medium-sized businesses and craft enterprises also have individual requirements for their tools and aids.

Through flexible production processes and efficient logistics, ZERVOS is able to produce even smaller quantities at high quality. This commitment to customized solutions reflects the manufacturing concept that each product is made with care and a high degree of "personalization" – whether it is custom-made or series-produced items.

Thus, ZERVOS not only supports large industries but also helps smaller companies optimize their processes and produce high-quality end products.

Responsible Production

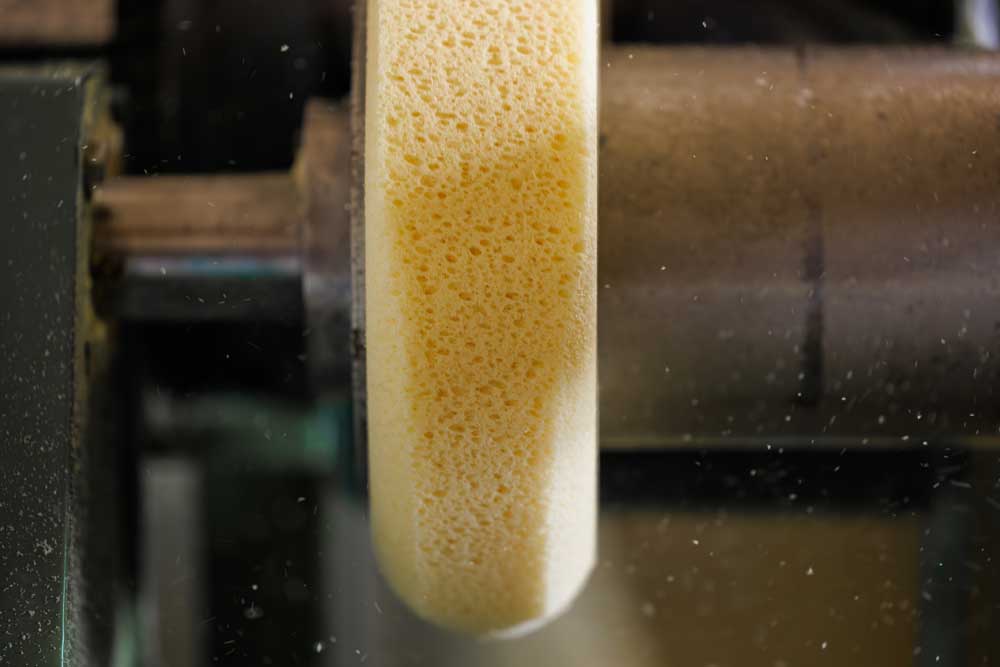

Our many years of experience and deep knowledge enable us to optimize production processes and minimize material waste. We utilize every sponge block to its fullest extent and ensure that all materials meeting our quality standards are fully processed. This approach not only minimizes waste but also maximizes resource efficiency.

During precise cutting of our PUR sponges, so-called by-products are produced in every production run. To take another step towards responsible production, we offer these cuttings at very attractive prices. Often, they only differ by a few millimeters from standard parameters; therefore, consult your production manager to see if using these cost-effective alternatives might be feasible for your operation.

Naturally, we assure you that even our foam by-products maintain our high-quality standards for PUR sponges. A detailed list of our offers can be found here.